Precision and Efficiency Redefined: Unveiling the Power of CNC Drilling Machines

CNC drilling machines are cutting-edge tools that have transformed the drilling landscape in various industries. CNC stands for Computer Numerical Control, which means these machines are controlled by computers to execute precise drilling operations. In this article, we will explore the functionality and impact of CNC drilling machines, understanding how they have revolutionized the manufacturing and fabrication processes.

Introduction to CNC Drilling Machines

- Definition and Functionality:

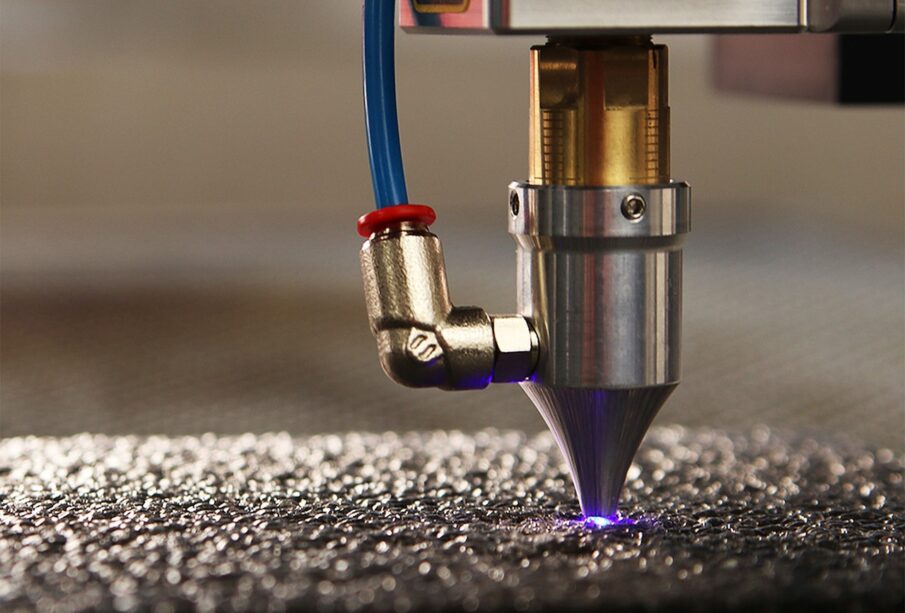

CNC drilling machine is advanced devices equipped with computer controls and automation features that enable them to execute drilling tasks with unparalleled precision and efficiency. These machines can accurately position and move the drill bit, allowing for complex hole patterns and intricate designs. The computer-controlled automation eliminates the need for manual adjustments, minimizing human errors and ensuring consistent results.

- How CNC Technology Revolutionized Drilling:

The integration of CNC technology into drilling machines has been a game-changer for the manufacturing industry. With CNC programming, operators can create detailed drilling instructions, specifying the hole sizes, depths, and positions, all with a few clicks. This level of automation and control allows for faster setup times and reduced production cycles, making CNC drilling machines highly productive and cost-effective.

Advantages and Applications of CNC Drilling Machines

- Precision and Accuracy in Drilling:

One of the most significant advantages of CNC drilling machines is their unmatched precision and accuracy. The computer-controlled movements ensure that each hole is drilled with the utmost precision, resulting in consistent hole diameters and depths. This level of accuracy is crucial in industries like aerospace and automotive, where even the smallest deviation can affect the performance and safety of components.

Moreover, CNC drilling machines can perform repetitive drilling tasks with identical precision, making them ideal for mass production. This capability significantly reduces the likelihood of errors and ensures that every finished product meets the required specifications.

- Versatility Across Industries:

CNC drilling machines find applications across various industries due to their versatility. They can work with different materials, including metals, plastics, composites, and even wood. This adaptability makes them valuable in industries ranging from aerospace and electronics to construction and woodworking.

In the aerospace industry, CNC drilling machines are used to create precise holes in aircraft components, such as wings, fuselage, and engine parts. In electronics manufacturing, these machines drill holes in printed circuit boards (PCBs) to accommodate electronic components. Additionally, CNC drilling machines play a vital role in the construction sector, where they are employed for drilling holes in steel beams, plates, and concrete structures.

Conclusion

CNC drilling machines have revolutionized the way drilling tasks are performed in modern industries. With their computer-controlled precision and automation, these machines have raised the bar for drilling accuracy and efficiency. Their versatility and widespread applications make them indispensable tools across various sectors, driving innovation, and shaping the future of manufacturing and fabrication processes. As CNC technology continues to advance, we can expect even more sophisticated and capable CNC drilling machines to further propel industries forward.